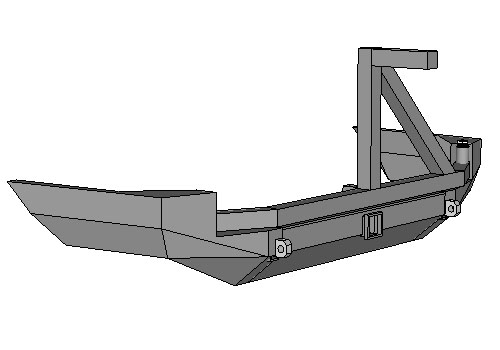

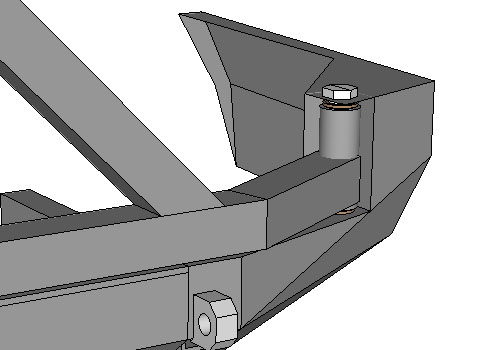

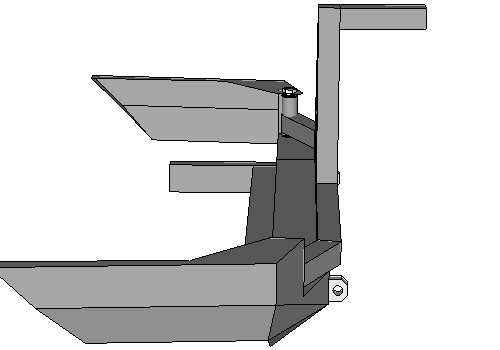

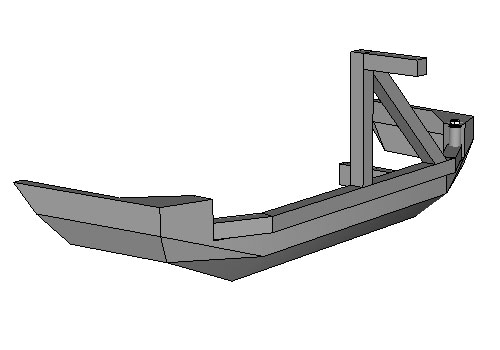

Description

Estimated Weight:

N/A

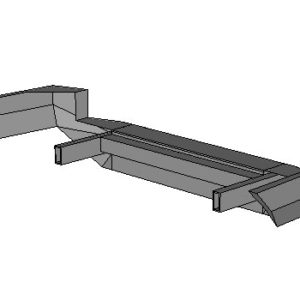

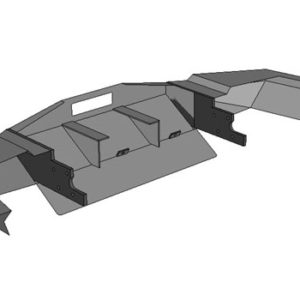

| Required Materials (Standard Version): | Required Materials (Hitch Version): |

| 48″ x 60″ steel plate – 3/16″ thickness 31.75″ x 1.5″ x 3″ tubing 1/4″ wall 34″ x 3″ x 3″ tubing 1/4″ wall 108″ x 2″ x 2″ tubing 3/16″ wall |

48″ x 48″ steel plate – 3/16″ thickness 31.75″ x 1.5″ x 3″ tubing 1/4″ wall 34″ x 3″ x 3″ tubing 1/4″ wall 108″ x 2″ x 2″ tubing 3/16″ wall 2″ Hitch Receiver Tube |

Suggested Materials:

Additional Gussets and Bracing As Needed

Grade 8 Hardware For Mounting

D-Ring Mounts

Daniel Z (verified owner) –

I’ll leave a review here since I’m back and there isn’t one currently: I built my Flatland4x4 rear bumper/carrier using 3/16″ A36 plus the tubing on my ZJ (’96 V-8 Laredo) several years back, and doing so was (in my view) the definitive moment when my Jeep went from stock-ish to clearly built and unique. I personally found the design of the rear bumper easier to put together than the front (part of that has to do with how you can mount the rear vs. what Jeep gave us in the front; not that I regret going Flatland4x4 on the front at all), and having a swing out carrier is awesome! I do recommend having better than a bargain basement welder, as any bumper build takes a lot of welds. As for the tire carrier: don’t be foolish and throw away money as I did on a fabricated round plate with drilled holes and studs welded in, you’re a Jeep guy/gal: save an old wheel hub and throw that thing on your carrier! Finally, welding in some square tube in the outer ends and putting a doubler plate where you bolt to the uniframe are some very good places to throw extra steel. Making a license plate mount and wiring up lights turned out to be the hardest task to figure out in the end (get yourself some outdoor automotive 12V connectors and some waterproof shrink-wrap for a pro-tier finish!). Overall, it’s a great set of plans and made for a very fun and rewarding project!